Tips for Improving Coupling Lifespan

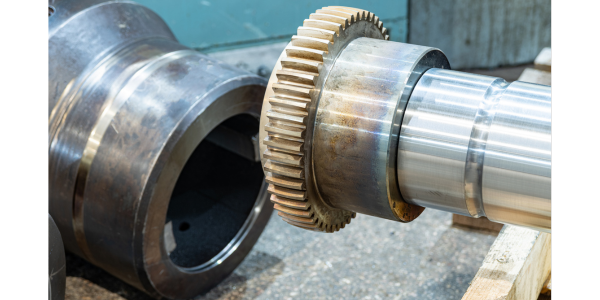

I. Introduction to Couplings

Couplings are mechanical devices used to connect two shafts together for transmitting power. They play a crucial role in various industries, ensuring the smooth transfer of torque while accommodating misalignment and vibration. Understanding how to extend their lifespan is vital for optimizing machinery performance.

II. Factors Affecting Coupling Lifespan

A. Environmental Conditions

Harsh environments, such as extreme temperatures, corrosive elements, and excessive moisture, can significantly impact coupling longevity. Exposure to these conditions can lead to accelerated wear and reduced efficiency.

B. Proper Maintenance Practices

Regular maintenance, including inspection, lubrication, and monitoring for signs of wear, is essential for ensuring optimal coupling performance. Neglecting maintenance can lead to premature failure.

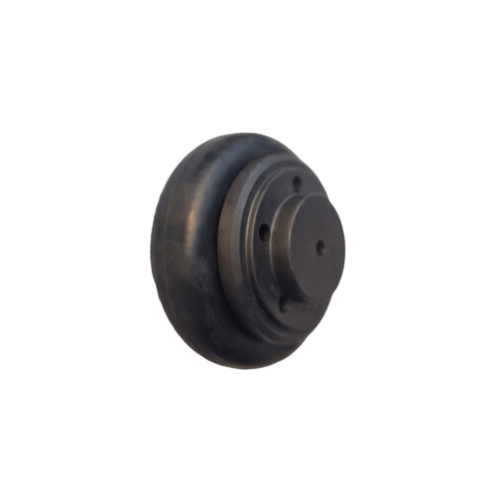

C. Material Quality

The quality of materials used in manufacturing couplings plays a significant role in determining their durability. High-quality materials are more resistant to wear and corrosion, contributing to a longer lifespan.

III. Tips for Improving Coupling Lifespan

A. Regular Inspection and Lubrication

Frequent inspections help identify early signs of wear or misalignment, allowing for timely maintenance. Proper lubrication reduces friction, preventing premature deterioration.

B. Correct Alignment and Installation

Proper alignment during installation is critical for the efficient operation of couplings. Misalignment can lead to increased stress, reducing their lifespan.

C. Temperature and Environmental Control

Maintaining suitable operating temperatures and controlling environmental factors can significantly impact coupling performance. Implementing measures to regulate these factors can extend their lifespan.

IV. Case Studies on Prolonging Coupling Life

A. Real-life Examples

Case studies highlighting successful strategies in prolonging coupling lifespan provide valuable insights. Examples demonstrating effective maintenance practices and material choices are beneficial for industry professionals.

B. Success Stories and Strategies Implemented

Exploring success stories from industries applying innovative strategies or utilizing advanced materials can offer inspiration and practical methods for extending coupling life.

V. Conclusion

Recap and Importance of Following Best Practices

In conclusion, understanding the factors influencing coupling lifespan and implementing proper maintenance practices are crucial for optimizing machinery performance. By adhering to best practices and learning from successful cases, industries can significantly extend coupling lifespan and reduce downtime.

Final Tips for Extending Coupling Lifespan

Regular inspections, proper lubrication, correct alignment, and consideration of environmental factors are key elements in ensuring a longer coupling lifespan.

Regular inspections are recommended, typically every three to six months, but frequency may vary based on usage and operating conditions.

High-quality couplings designed for specific temperature ranges can endure extreme temperatures effectively.

Correct alignment during installation prevents excessive stress and wear, prolonging the coupling's life.

Yes, exposure to harsh environmental conditions can accelerate wear and reduce the lifespan of couplings.