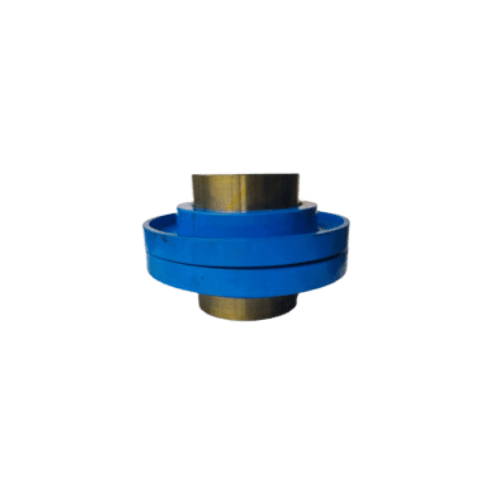

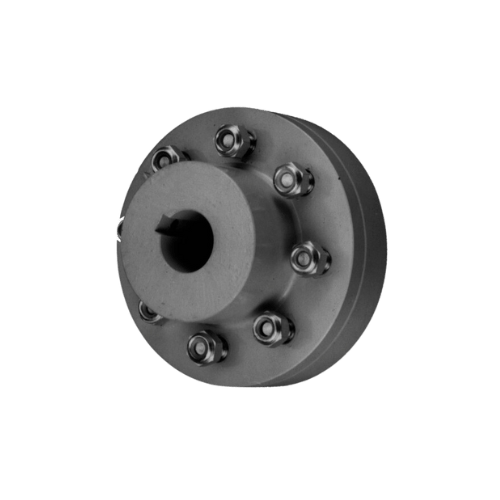

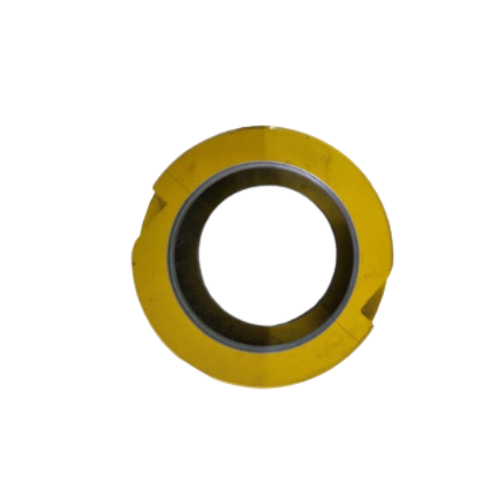

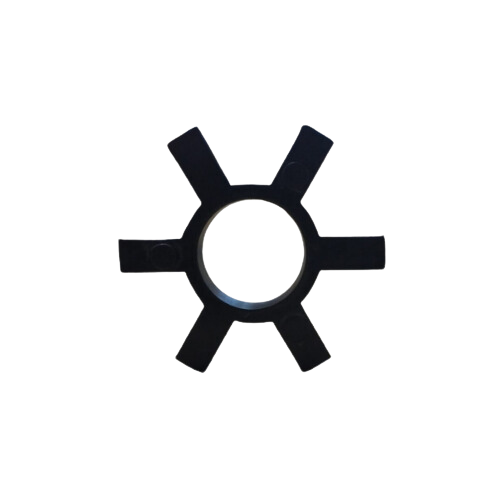

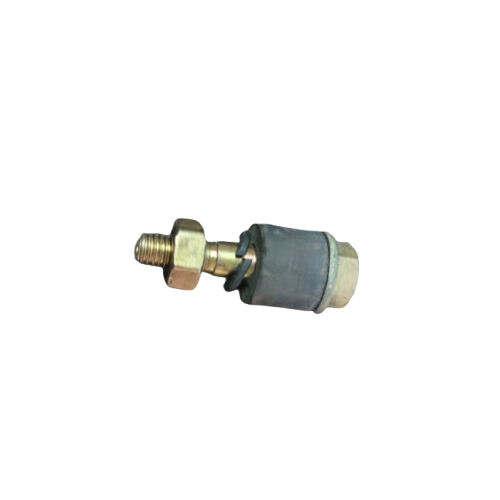

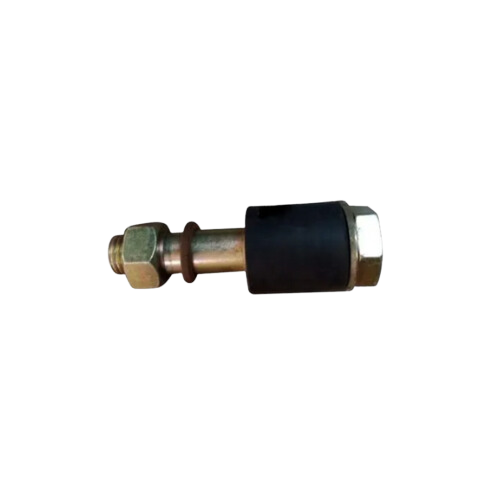

ALUMINIUM COUPLING

Introduction to Aluminium Couplings

Aluminium Coupling stand as pivotal elements across myriad industries, The Coupling House facilitating the linkage of pipes, tubes, and diverse apparatuses. These adaptable fittings proffer a plethora of advantages and enjoy widespread utility in varying domains. Within this discourse, we shall delve into the realm of aluminium Coupling, exploring their diverse classifications, merits, applications, and more.

Aluminium Coupling function as interlinks within plumbing, HVAC systems, industrial apparatuses, and automotive realms. They assume a pivotal role in securely uniting two pipes or tubes, ensuring a watertight joint.

Understanding Aluminium Coupling

Aluminium Coupling represent fittings forged from premium aluminium alloys, engineered to furnish robustness, endurance, and resistance to corrosion. These Coupling manifest in diverse configurations and dimensions to suit varying pipe diameters and connection requisites.

Advantages of Aluminium Coupling

Aluminium Coupling proffer myriad benefits over alternative materials, including:

- Featherweight and facile to manipulate

- Exceptional resistance to corrosion

- Elevated strength-to-mass ratio

- Economical solution

- Recyclable and eco-friendly

Applications of Aluminium Coupling

Aluminium Coupling enjoy extensive application across a spectrum of industries such as:

- Hydraulic and irrigation systems

- HVAC (Heating, Ventilation, and Air Conditioning)

- Automobile fabrication

- Aerospace engineering

- Maritime and offshore installations

Considerations Before Opting for Aluminium Coupling

When electing aluminium Coupling for specific applications, it is imperative to contemplate factors like:

- Operating parameters (pressure, temperature, and medium)

- Diameter and material of the pipe/tube

- Compatibility with other constituents

- Installation prerequisites and spatial constraints

Installation Protocol of Aluminium Coupling

The installation of aluminium Coupling encompasses the ensuing steps:

- Prepare the pipes or tubes by cleansing and deburring the terminations.

- Administer lubricant or sealant to the connection threads.

- Glide the connection onto one extremity of the pipe/tube.

- Align the secondary pipe/tube and firmly secure the connection.

- Scrutinize for leaks and effectuate adjustments as warranted.

Maintenance Guidelines for Aluminium Coupling

To ensure peak functionality and durability, adhere to these maintenance guidelines:

- Routinely scrutinize Coupling for indications of wear or impairment.

- Clean Coupling employing a mild detergent and aqueous solution.

- Lubricate threads and seals as necessitated.

- Expediently substitute worn or corroded Coupling to forestall leaks.

Typical Predicaments and Remedial Measures

Common quandaries associated with aluminium Coupling encompass:

- Seepages attributable to faulty installation or compromised seals

- Corrosion stemming from exposure to rigorous environs

- Thread seizing or stripping during assembly

Mitigating these predicaments may entail tightening Coupling, substituting seals, or employing coatings resistant to corrosion.

Safety Precautions During Utilization of Aluminium Coupling

When manipulating and installing aluminium Coupling, observe the ensuing safety precautions:

- Don suitable personal protective gear (PPE), encompassing gloves and safety goggles.

- Refrain from over-tightening Coupling, as this may jeopardize threads or induce leaks.

- Exercise caution when interfacing with pressurized systems to avert mishaps.

Prospective in Aluminium Coupling Technology

The trajectory of aluminium Coupling technology may entail innovations in:

- Material science to augment robustness and endurance

- Optimization of design to enhance performance

- Assimilation of smart technologies for real-time oversight and upkeep

Environmental Ramifications of Aluminium Coupling

Aluminium Coupling yield a relatively negligible environmental footprint vis-à-vis alternative material. They are recyclable and contribute to conservation of resources and endeavors toward sustainability.