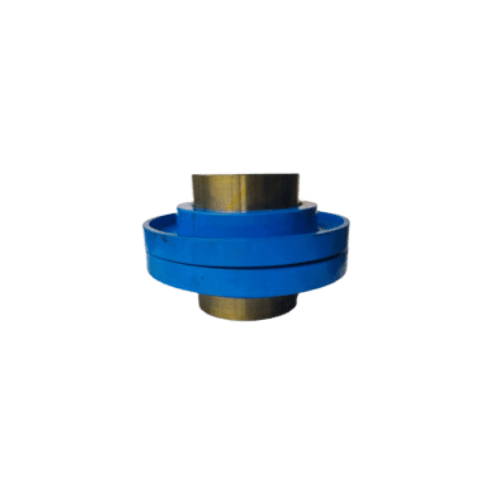

JAW COUPLING SPARES

Introduction of Jaw Coupling Spares

At Coupling House, we understand the critical role that jaw coupling spares play in maintaining machinery performance and preventing costly downtime. In this comprehensive guide, we delve into the intricate details of jaw coupling spares, offering valuable insights into their components, types, maintenance, and more.

Components of Jaw Coupling Spares

Jaw coupling spares comprise several vital components, each contributing to the smooth operation and longevity of machinery. These components include:

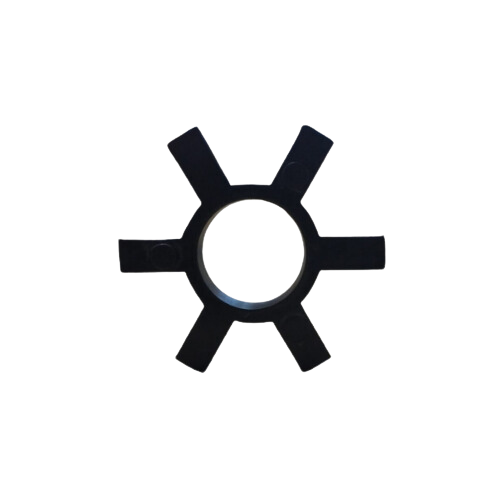

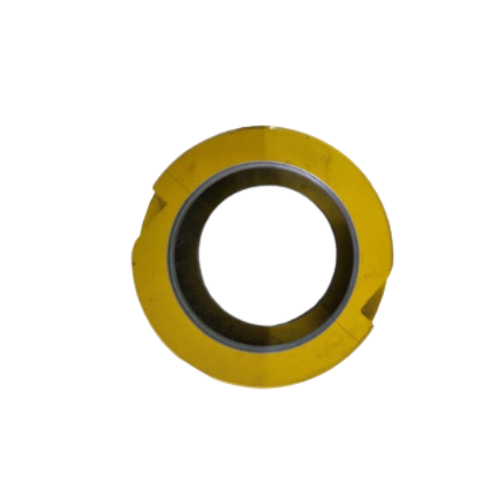

- Spider: The spider acts as a flexible element, accommodating misalignment and reducing shock loads.

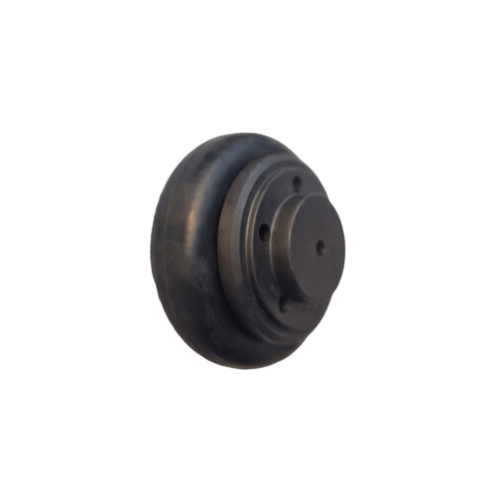

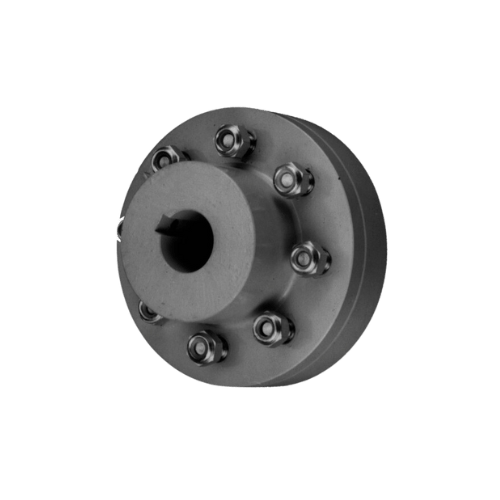

- Hub: The hub serves as the connection point between the shaft and the coupling.

Understanding the function of each component is crucial for selecting the right spares and maintaining optimal performance.

Types of Jaw Coupling Spares

When it comes to jaw coupling spares, there are two main types: metallic and non-metallic.

- Metallic Spares: Ideal for heavy-duty applications, metallic spares offer robustness and durability, making them suitable for demanding industrial environments.

- Non-metallic Spares: Non-metallic spares provide advantages such as corrosion resistance and vibration dampening, making them ideal for applications where cleanliness and quiet operation are paramount.

Choosing the appropriate type of spares depends on factors such as the application requirements and environmental conditions.

Signs of Wear and Tear

Detecting signs of wear and tear in jaw coupling spares is crucial for preventing unexpected failures and minimizing downtime. Some common indicators include:

- Vibrations: Excessive vibrations during operation can signal misalignment or worn components.

- Misalignment: Misalignment between shafts can accelerate wear and lead to premature failure.

- Unusual Noise: Any unusual noise, such as clicking or grinding, may indicate worn or damaged components.

Regular inspection and maintenance can help identify these signs early, allowing for timely replacement of spares and preventing costly repairs.

Importance of Maintenance

Maintaining jaw coupling spares is essential for prolonging equipment life, reducing downtime, and ensuring workplace safety. Neglecting maintenance can lead to:

- Costly Repairs: Failure to replace worn spares can result in damage to other components, leading to costly repairs.

- Decreased Performance: Worn or damaged spares can compromise machinery performance, affecting productivity and efficiency.

- Safety Hazards: Failed components pose safety risks to operators and nearby personnel, emphasizing the importance of regular maintenance.

Implementing a proactive maintenance schedule helps mitigate these risks, ensuring smooth operation and maximizing equipment lifespan.

Identifying the Right Jaw Coupling Spares

Selecting the right jaw coupling spares requires careful consideration of various factors, including:

- Compatibility: Spares must be compatible with existing equipment to ensure proper functioning and alignment.

- Quality: Opting for genuine spares from reputable manufacturers guarantees quality and reliability, minimizing the risk of premature failure.

- Ease of Installation: Spares should be easy to install, reducing downtime and labor costs associated with replacement.

By prioritizing these factors, operators can ensure optimal performance and longevity of their machinery.

Replacing Jaw Coupling Spares: Step-by-Step Guide

When replacing jaw coupling spares, following a systematic approach is essential to ensure proper installation and alignment. The process typically involves:

- Inspection: Thoroughly inspect the coupling assembly for signs of wear or damage.

- Removal: Carefully remove the old components, taking note of their orientation and alignment.

- Installation: Install the new spares according to manufacturer guidelines, ensuring proper alignment and torque specifications.

- Testing: Conduct a test run to verify the alignment and functionality of the new spares.

Adhering to these steps helps prevent errors and ensures smooth operation of the machinery.

Common Mistakes to Avoid

Avoiding common mistakes is crucial for maximizing the efficiency and lifespan of machinery. Some pitfalls to avoid include:

- Neglecting Inspection: Failing to inspect spares regularly can lead to undetected wear and premature failure.

- Using Incompatible Spares: Using spares that are not compatible with the equipment can result in poor performance and increased wear.

- Improper Installation: Incorrect installation can lead to misalignment and premature failure of components.

By avoiding these mistakes and prioritizing proactive maintenance, operators can optimize machinery performance and minimize downtime.

Benefits of Using Genuine Jaw Coupling Spares

Investing in genuine jaw coupling spares offers numerous benefits, including:

- Optimal Performance: Genuine spares are designed to exact specifications, ensuring compatibility and optimal performance.

- Longevity of Machinery: Quality spares help prolong the lifespan of machinery, reducing the frequency of replacements and associated costs.

- Warranty Coverage: Genuine spares often come with warranty coverage, providing peace of mind and protection against defects.

While the initial cost may be higher, the long-term benefits outweigh the investment, resulting in significant cost savings and operational efficiency.

Cost Considerations

While cost is an important factor in purchasing decisions, it's essential to consider the long-term implications. While genuine spares may have a higher initial cost, they offer:

- Superior Quality: Genuine spares are manufactured to stringent quality standards, ensuring reliability and durability.

- Reduced Downtime: High-quality spares minimize the risk of unexpected failures, reducing downtime and associated costs.

- Long-Term Savings: Investing in quality spares results in long-term savings by minimizing repair and replacement costs.

By weighing these factors, operators can make informed decisions that optimize both performance and cost-effectiveness.

Availability of Jaw Coupling Spares

Jaw coupling spares are readily available from Coupling House, when sourcing spares, it's crucial to choose a reputable supplier and verify the authenticity of the products to ensure reliability and performance.

Customer Reviews and Feedback

Before making a purchase, it's advisable to research customer reviews and testimonials to gauge the quality and reliability of the products. Feedback from other users provides valuable insights into the performance and suitability of specific spares, helping operators make informed decisions.

Future Trends in Jaw Coupling Spares

Advancements in materials and design are driving innovation in jaw coupling spares, leading to improved performance and efficiency. The integration of IoT technology for predictive maintenance is poised to revolutionize the way spares are monitored and replaced, offering enhanced reliability and cost savings.