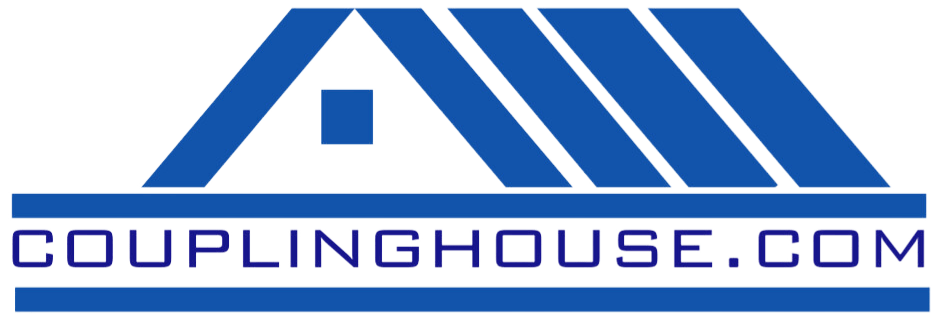

JAW COUPLING SPIDER

Introduction to Jaw Coupling Spiders

Jaw coupling spiders play a pivotal role in numerous mechanical systems, offering unparalleled flexibility and torsional damping capabilities. At Coupling House, we understand the importance of these components in maintaining smooth operations across various industries. In this comprehensive guide, we delve into the intricacies of jaw coupling spiders, exploring their types, design, advantages, applications, selection considerations, installation, maintenance, common issues, troubleshooting, and future trends.

Types of Jaw Coupling Spiders

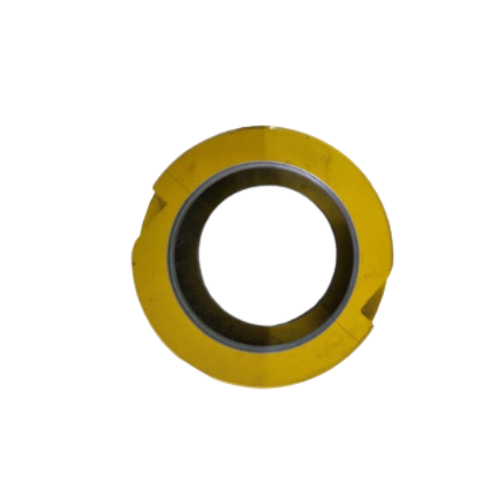

Elastomeric Jaw Coupling Spiders

Elastomeric jaw coupling spiders are crafted from resilient materials such as polyurethane or rubber. Renowned for their high flexibility and damping properties, these spiders excel in applications where vibration reduction is paramount. Their ability to absorb shocks and compensate for misalignments makes them ideal for diverse industrial settings.

Metallic Jaw Coupling Spiders

Contrasting with their elastomeric counterparts, metallic jaw coupling spiders are engineered from robust materials like steel or aluminum. These spiders prioritize strength and resistance to high temperatures, catering to demanding environments where durability is key. Their rigid construction ensures reliable torque transmission and longevity.

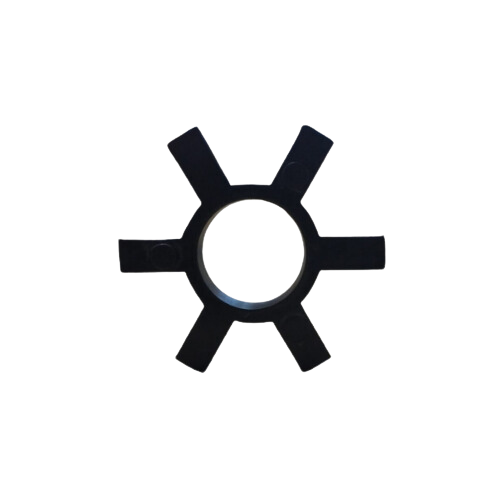

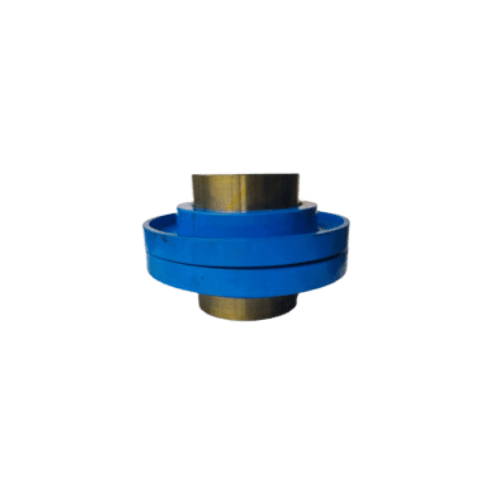

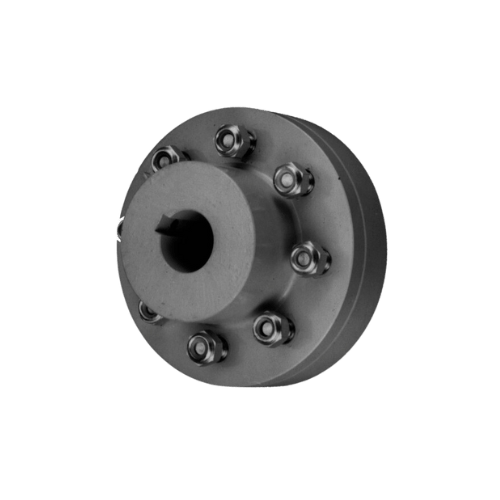

Design and Functionality

A typical jaw coupling spider comprises two hubs with interlocking teeth and a central spider element. The spider, often elastomeric in nature, features slots that mesh with the teeth of the hubs, facilitating a flexible connection. When subjected to torque, the spider undergoes controlled deformation, accommodating shaft misalignment and dampening vibrations to safeguard machinery components.

Advantages of Using Jaw Coupling Spiders

Misalignment Compensation

One of the foremost advantages of jaw coupling spiders is their ability to accommodate shaft misalignment. By mitigating misalignment, these spiders minimize wear and tear on equipment, thereby enhancing operational efficiency and longevity.

Torsional Flexibility

Jaw coupling spiders offer exceptional torsional flexibility, effectively shielding sensitive components from damage caused by sudden shocks or vibrations. This attribute is particularly crucial in applications where precise torque transmission is essential for optimal performance.

Cost-Effectiveness

In addition to their performance benefits, jaw coupling spiders boast a cost-effective design. Their minimal maintenance requirements and extended service life translate to reduced downtime and enhanced cost savings for businesses.

Applications of Jaw Coupling Spiders

Jaw coupling spiders find widespread utility across various industries, including:

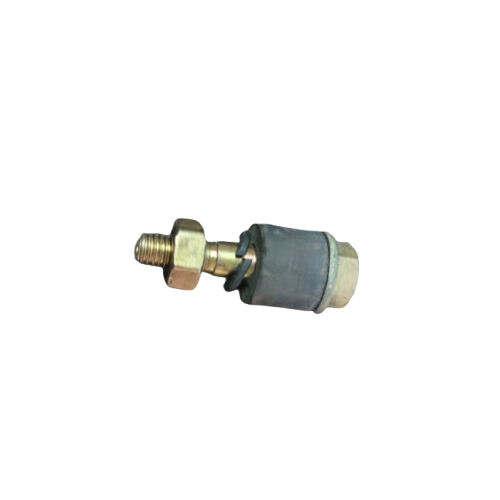

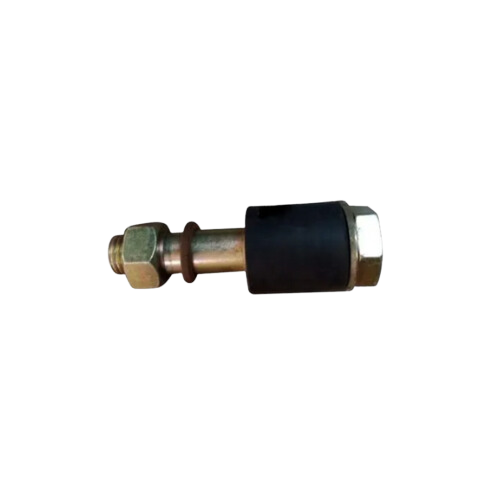

Industrial Machinery: From heavy-duty pumps to precision machining equipment, jaw coupling spiders are integral components in a myriad of industrial machinery applications.

Automotive Systems: In the automotive sector, these spiders contribute to the smooth operation of transmissions, steering systems, and other critical components.

Aerospace Industry: Even in the aerospace industry, where stringent performance standards prevail, jaw coupling spiders play a vital role in ensuring the reliability of propulsion systems and flight control mechanisms.

Factors to Consider When Choosing Jaw Coupling Spiders

Torque Requirements

The selection of jaw coupling spiders hinges on the specific torque demands of the application. It's imperative to choose spiders capable of transmitting the requisite torque without compromising performance or safety.

Environmental Conditions

Environmental factors such as temperature variations and chemical exposure can impact the performance and longevity of jaw coupling spiders. Selecting spiders engineered to withstand these conditions is paramount to ensuring reliability and longevity.

Shaft Misalignment Tolerance

Different applications may necessitate varying degrees of shaft misalignment tolerance. Choosing jaw coupling spiders with appropriate misalignment capabilities is essential to prevent premature wear and ensure optimal performance.

Installation and Maintenance Tips

Follow Manufacturer Guidelines

Adhering to manufacturer guidelines and torque specifications during installation is critical to maximizing the performance and lifespan of jaw coupling spiders. Deviating from recommended practices can lead to premature failure and costly downtime.

Regular Maintenance

Routine visual inspections for wear and tear, coupled with periodic lubrication, can significantly extend the service life of jaw coupling spiders. Investing in proactive maintenance measures is key to avoiding unexpected breakdowns and disruptions to operations.

Common Issues and Troubleshooting

Misalignment

Misalignment is a common issue that can compromise the performance and longevity of jaw coupling spiders. Regular inspection and realignment are essential to mitigate the effects of misalignment and prevent premature failure.

Wear and Vibration

Excessive wear or vibration may indicate underlying issues with jaw coupling spiders or associated machinery components. Prompt troubleshooting and replacement of worn-out parts are crucial to maintaining optimal performance and minimizing downtime.

Future Trends in Jaw Coupling Spider Technology

Advancements in materials science and manufacturing processes are driving continuous innovation in jaw coupling spider technology. New materials with enhanced damping properties and temperature resistance are revolutionizing the capabilities of these components, enabling them to thrive in increasingly demanding applications. Furthermore, the integration of jaw coupling spiders with IoT technology holds promise for predictive maintenance strategies, ushering in an era of proactive equipment management and enhanced operational efficiency.